![]() Home - Products - Collagen Casings - Fresh Casings

Home - Products - Collagen Casings - Fresh Casings

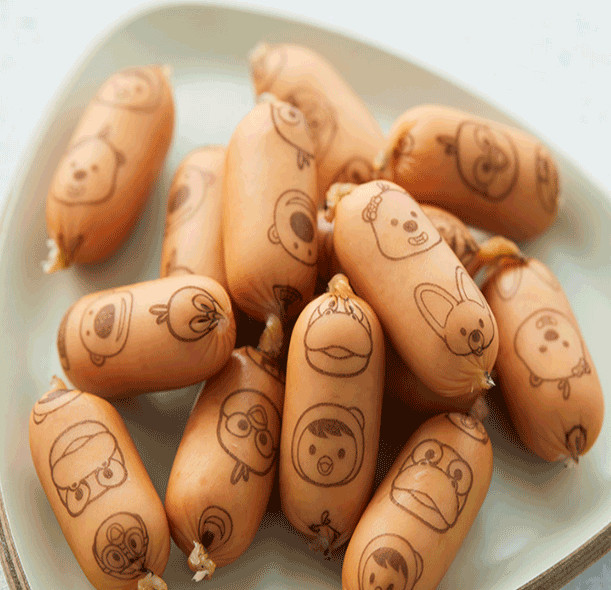

Fresh Sausage Casings are made from natural collagen material from hides with extra performance characteristics added customized for this application. They are carefully prepared with specialized technology specifically for use in various types of Fresh Sausage products, such as Fresh Meat sausage, Breakfast sausage, and BBQ sausage.

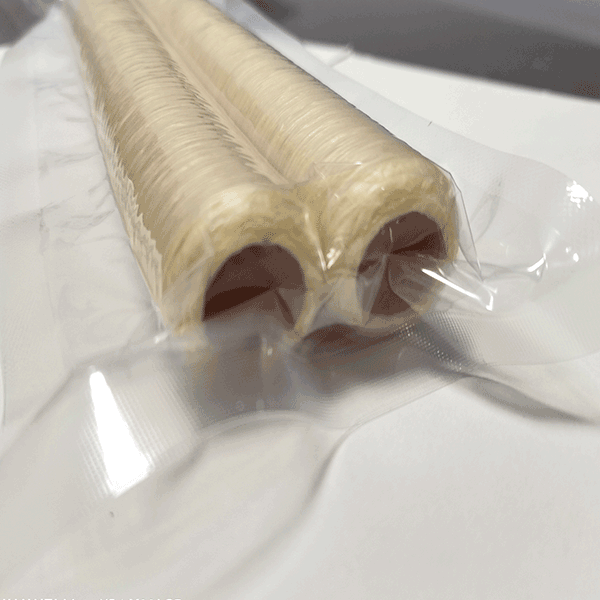

Collagen casings are made from high-quality natural collagen from animal hides, so they are edible. Collagen casings are highly permeable to smoke and moisture. The casing is fully adhered to the sausage, become part of the formulation, and therefore is fully edible. We have special formulations to ensure the casing adheres fully to all types of sausages, whether it’s shrinkage or stretching during filling and cooking. Collagen casings have 20 ~ 30% higher smokehouse productivity compared to natural casings. The production process does not need extra cleaning. No selection for sizing nor preparatory work is required. Collagen casing are highly suited for mechanical filling. The shape and size of sausages are highly regular and consistent due to our unique process innovations.

Fresh Sausage Casings are made from natural collagen material from hides with extra performance characteristics added customized for this application. They are carefully prepared with specialized technology specifically for use in various types of Fresh Sausage products, such as Fresh Meat sausage, Breakfast sausage, and BBQ sausage.

Production:

The production of collagen casings can be roughly divided into three steps:

1.Pretreatment

The epidermis is removed from the animal skin, and the dermis is soaked in lye to remove keratin and other soluble components, and then the skin is swollen by washing and acid leaching.

2.Extrusion molding

The swollen skin is cut into strips, and then cut into small particles. It is beaten into paste (glue) by mechanical method, and the solid content is adjusted. The pipe is extruder by special nozzle.

3.Set and dry

Dry setting (direct drying with hot air) or wet setting (first setting with coagulation bath, then drying with hot air), and then cross-linked with cross-linking agent, dried, and cut to make collagen casing finished products.

Jenna Zhang +86 15853655157 / Alen Cong +86 18953676009

sales@sunricasing.com / sales01@sunricasing.com

No.215,Building 4,Zhongkai Xingye Trade Square,No.45000,Haigang Road,Hanting District,Weifang City,Shandong Province,China

Links: